Compressive Strength Testing

Plastic Flow, Ductile Fracture, & Compressive Failure Mode Analysis

What is Compressive Strength Testing?

Compressive strength testing is performed by "squishing" a sample under bi-axial compressive loading. This allows engineers to observe how a material or product performs and fails under stress. Compression testing is performed on many materials that are "stronger" in compression than tension, or vice versa. For example, concrete is much stronger under compression than tension. Steel on the other hand, is stronger in tension. This is why steel-reinforced concrete columns are used in building construction. The concrete bears the weight of the building while the steel protects the structure from shear and torsion.

Our Equipment

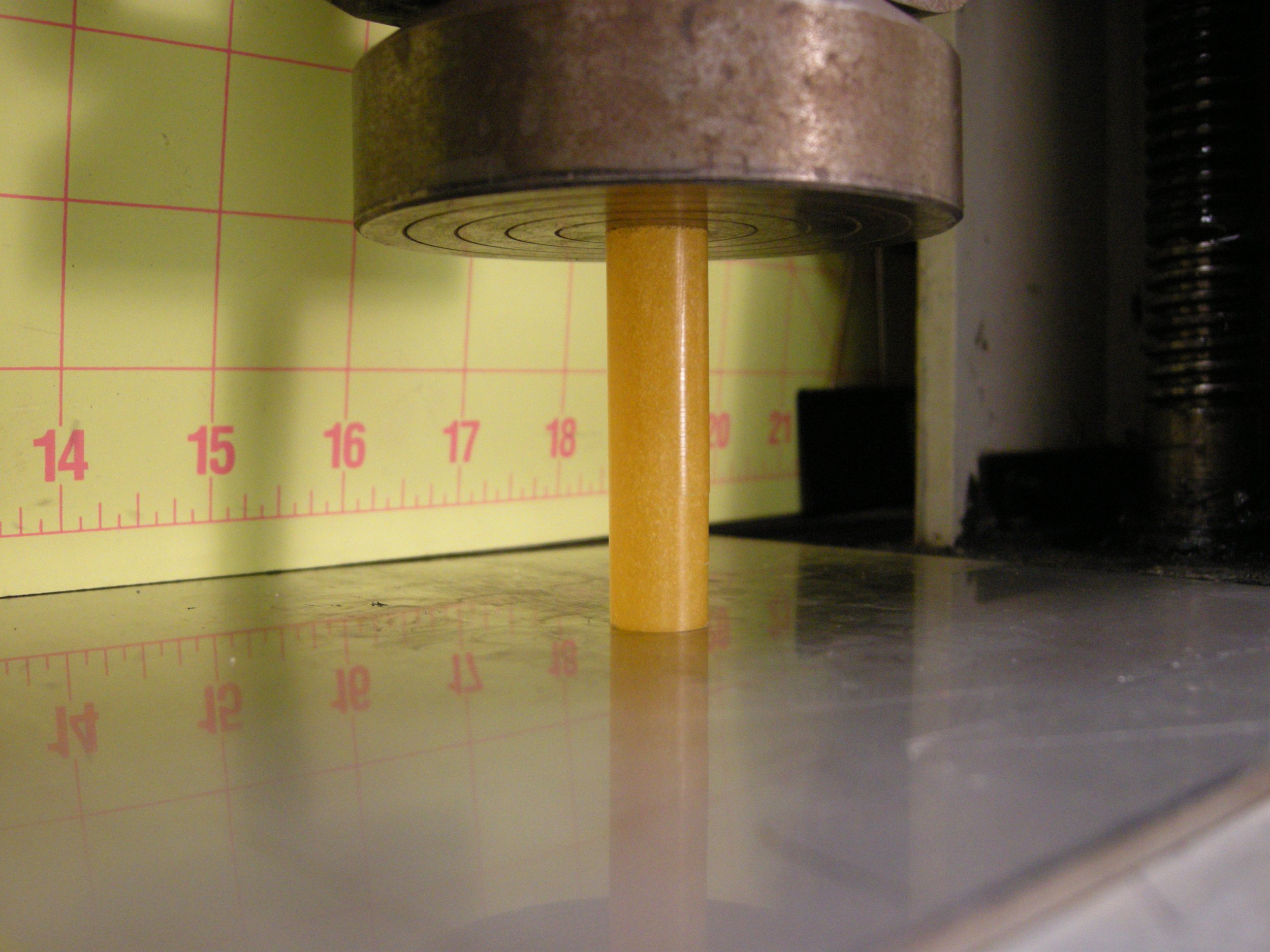

FAI operates Instron universal load frames with compression plates for our compressive strength testing. To learn more about our equipment, check out our page on our Instron universal load frames.

Test Specimens

Most compression test specimens are either right, flat-topped cylinders or rectangular blocks. But, compression tests can also be performed on full-size or scaled models of products or components. We test materials and components and provide graphs of physical properties determined from the compressive testing such as ultimate compressive strength, failure mode, and more.

Case Studies: Tool Handle

Related Services: Tensile Testing

Contact us for more information.